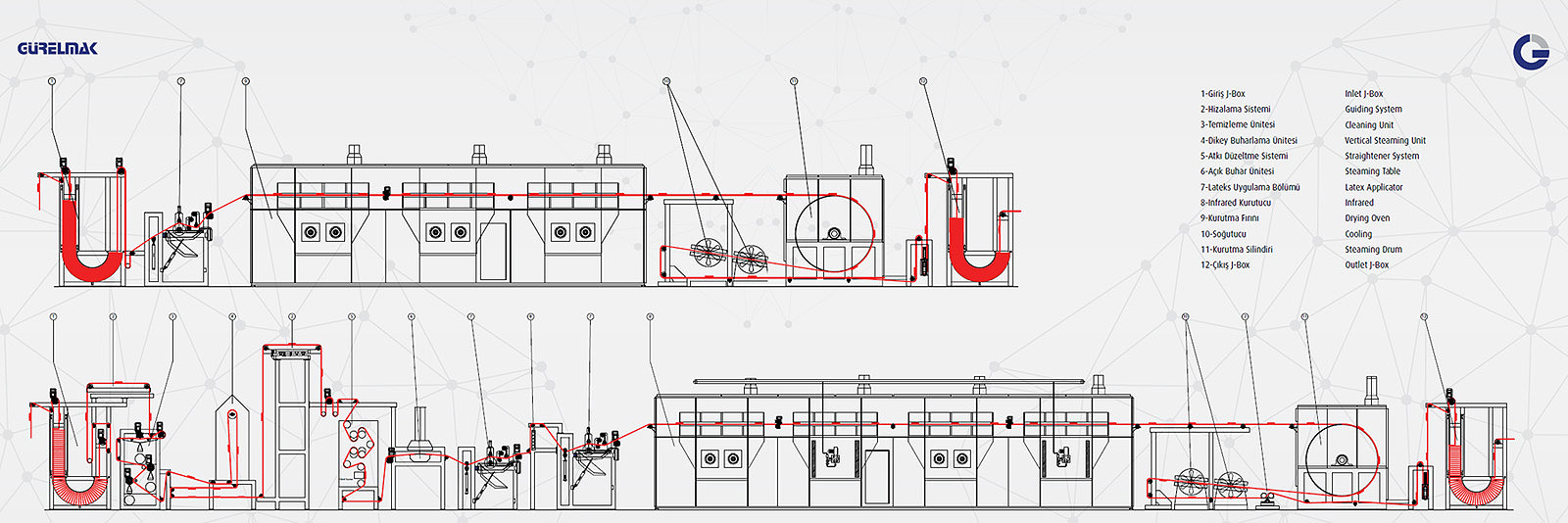

CARPET BACKCOATING LINE

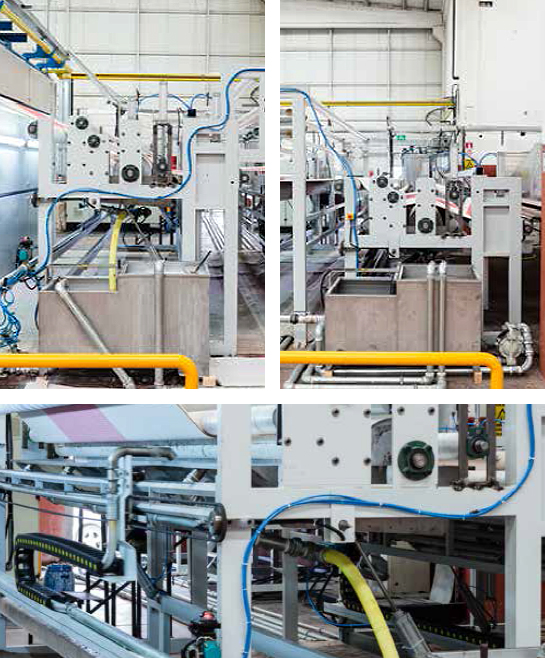

Latex Applicator

Steaming Drum

Cooling - Centering

It is the unit that cooled carpet are centered and stored at the J-box in order to be ready for sheaving.

Centering Unit

It helps carpets coming from vertical steaming to latexing unit properly.

Vertical Steaming

It enables surface effect to carpets in which high bulk yarns are used by using necessary heat and steam

Automatic Latex Preparation & Transport System

Glazing Roller

It features bright surface by ensuring the glazing of pile section of the carpet.

Pre-Drying With Infrared

It ensures fast drying of first application in case of using two different latex applications.

Open Steaming Unit

It applies open steaming through the back of the carpet before latexing unit.

Sewing Unit